Measured Data

Specific Heat

Experiments for specific heat [J/(kg K)], or heat capacity, were conducted using a heat flow meter on unconditioned and dried samples at 10 °C, 20 °C, 30 °C and 40 °C.

Unconditioned

| Temperature (C) | Specific Heat Mean (J/kg-K) | Standard Deviation (J/kg-K) |

|---|---|---|

| 10.0 | 1379.0 | 8.0 |

| 20.0 | 1403.0 | 6.0 |

| 30.0 | 1439.0 | 1.0 |

| 40.0 | 1459.0 | 7.0 |

Thermal Conductivity

Experiments for thermal conductivity [k] were conducted using a heat flow meter on unconditioned samples at 15 °C and 45 °C.

Unconditioned

| Temperature (C) | Conductivity Mean (W/m-K) | Standard Deviation (W/m-K) |

|---|---|---|

| 15.0 | 0.133 | 0.004 |

| 45.0 | 0.144 | 0.003 |

Mass Loss Rate (MLR)

Mass loss rate [g/s] was measured in cone calorimeter experiments at three heat fluxes: 25 kW/m2, 50 kW/m2, and 75 kW/m2.

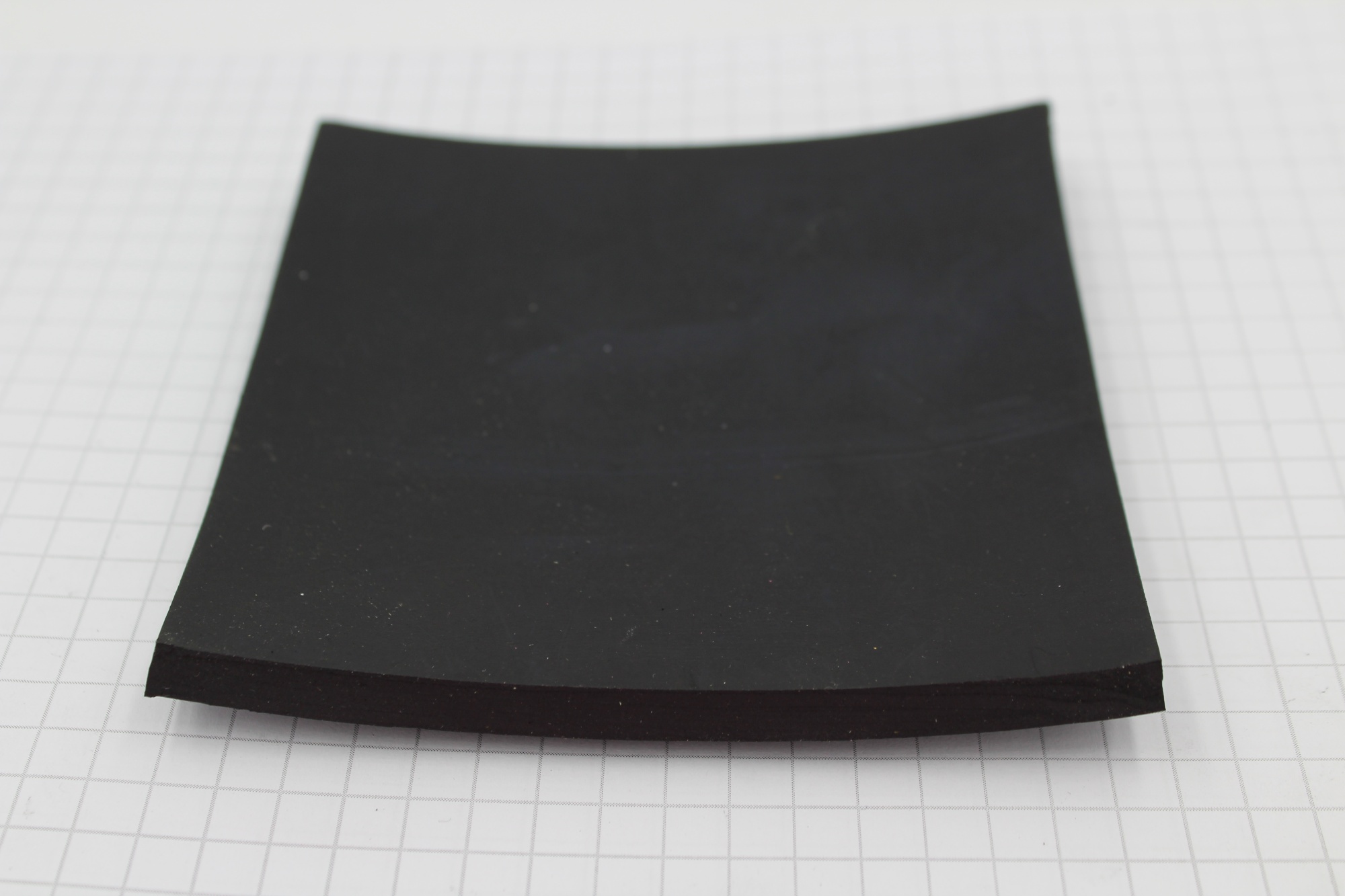

This material warps and intumesces after ignition. An edge frame and wire grid were used to limit this behavior, yet the sample still expanded vertically through the wire grid, in some cases by more than 2 cm. One additional replicate was conducted per heat flux level without the wire grid to acquire more accurate time to ignition data (HF25_R2, HF50_R4, HF75_R4). Another test was conducted at 25 kW/m2 without either the edge frame or wire grid (HF25_R1) to observe the material burning behavior without intervention. For individual test notes and select test pictures, follow the link above to Download raw data.

Cone Calorimeter: 25 kW/m2

Cone Calorimeter: 50 kW/m2

Cone Calorimeter: 75 kW/m2

Heat Release Rate Per Unit Area (HRRPUA)

Experiments for heat release per unit area [kW/m2] were conducted on samples conditioned at 20°C and 50% relative humidity using a cone calorimeter at three different heat fluxes: 25 kW/m2, 50 kW/m2, and 75 kW/m2.

This material warps and intumesces after ignition. An edge frame and wire grid were used to limit this behavior, yet the sample still expanded vertically through the wire grid, in some cases by more than 2 cm. One additional replicate was conducted per heat flux level without the wire grid to acquire more accurate time to ignition data (HF25_R2, HF50_R4, HF75_R4). Another test was conducted at 25 kW/m2 without either the edge frame or wire grid (HF25_R1) to observe the material burning behavior without intervention. For individual test notes and select test pictures, follow the link above to Download raw data.

Cone Calorimeter: 25 kW/m2

Cone Calorimeter: 50 kW/m2

Cone Calorimeter: 75 kW/m2

Carbon Monoxide (CO) Yield

Carbon monoxide yield was measured during cone calorimeter experiments conducted at heat fluxes of 25 kW/m2, 50 kW/m2, and 75 kW/m2.

This material warps and intumesces after ignition. An edge frame and wire grid were used to limit this behavior, yet the sample still expanded vertically through the wire grid, in some cases by more than 2 cm. One additional replicate was conducted per heat flux level without the wire grid to acquire more accurate time to ignition data (HF25_R2, HF50_R4, HF75_R4). Another test was conducted at 25 kW/m2 without either the edge frame or wire grid (HF25_R1) to observe the material burning behavior without intervention. For individual test notes and select test pictures, follow the link above to Download raw data.

| Incident Heat Flux [kW/m²] | Mean CO Yield [g/g] | CO Yield Std. Dev. [g/g] |

|---|---|---|

| 25 | 0.049 | 0.005 |

| 50 | 0.046 | 0.003 |

| 75 | 0.046 | 0.002 |

Specific Heat Release Rate

Experiments for specific heat release rate [W/g], were conducted using a micro-scale combustion calorimeter at a heating rate of 30 K/min.

Derived Data

Soot Yield

Soot yield [g/g] was calculated from smoke obscuration data collected in cone calorimeter experiments conducted at heat fluxes of 25 kW/m2, 50 kW/m2, and 75 kW/m2.

This material warps and intumesces after ignition. An edge frame and wire grid were used to limit this behavior, yet the sample still expanded vertically through the wire grid, in some cases by more than 2 cm. One additional replicate was conducted per heat flux level without the wire grid to acquire more accurate time to ignition data (HF25_R2, HF50_R4, HF75_R4). Another test was conducted at 25 kW/m2 without either the edge frame or wire grid (HF25_R1) to observe the material burning behavior without intervention. For individual test notes and select test pictures, follow the link above to Download raw data.

| Incident Heat Flux [kW/m²] | Mean Soot Yield [g/g] | Soot Yield Std. Dev. [g/g] |

|---|---|---|

| 25 | 0.149 | 0.008 |

| 50 | 0.155 | 0.017 |

| 75 | 0.152 | 0.01 |

Effective Heat of Combustion (Δhc)

Effective heat of combustion [MJ/kg] is calculated from data collected in both micro-scale combustion calorimeter experiments and cone calorimeter experiments.

Cone Calorimeter Test Notes:

This material warps and intumesces after ignition. An edge frame and wire grid were used to limit this behavior, yet the sample still expanded vertically through the wire grid, in some cases by more than 2 cm. One additional replicate was conducted per heat flux level without the wire grid to acquire more accurate time to ignition data (HF25_R2, HF50_R4, HF75_R4). Another test was conducted at 25 kW/m2 without either the edge frame or wire grid (HF25_R1) to observe the material burning behavior without intervention. For individual test notes and select test pictures, follow the link above to Download raw data.

Micro-scale Combustion Calorimeter

| Value | R1 | R2 | R3 | Mean | Std. Dev. |

|---|---|---|---|---|---|

| Heat of Combustion (MJ/kg) | 33.62 | 35.13 | 33.24 | 34.0 | 0.82 |

Cone Calorimeter

| Incident Heat Flux [kW/m²] | Mean Effective Heat of Combustion [MJ/kg] | Effective Heat of Combustion Std. Dev. [MJ/kg] |

|---|---|---|

| 25 | 36.7 | 1.6 |

| 50 | 35.4 | 1.0 |

| 75 | 33.1 | 0.9 |